How to determine shipping box size

Choosing the right shipping box size involves more than just packing your product. It impacts cost, protection, and the customer’s unboxing experience. If the box is too big, it wastes your shipping costs; if it’s too small, your product might get damaged. This article will show you how to measure the correct shipping box size.

This article will answer your questions

- Why shipping box size matters

- How to measure product and box dimensions

- How to reserve space for buffer materials

- Common standard shipping box sizes for e-commerce

- How to avoid extra shipping charges due to size

Why is choosing the correct shipping box size important?

Box size directly impacts shipping costs, product safety, and customer satisfaction. Courier companies like DHL, UPS, and FedEx charge based on dimensional weight, not the actual weight of the product. Oversized boxes increase shipping costs, while undersized boxes increase the risk of damage.

Excessive gaps in the outer box can make you look unprofessional. A properly sized box reduces waste and enhances your brand image. In logistics, the right box size can save 10–20% of shipping space.

How much does box size affect shipping costs?

| Box Types | Billing Weight | Extra Cost Impact | What It Means for You |

| Oversized | Dimensional weight ↑ | +15–30% higher fees | Unnecessary spending |

| Undersized | Damage rate ↑ | More returns | Profit loss |

| Right-Sized | Balanced cost & safety | Minimal extra charges | Efficient, safe, better experience |

- Fragile items: Allow 20–40 mm of space.

- Heavy objects: Choose double-layer corrugated paper (BC corrugated paper).

- Air freight: The smaller and lighter the package, the less expensive it is.

Real-world case study: A cosmetics brand in Shenzhen reduced its boxes by 15%, saving 12% on DHL shipping costs while also reducing the breakage rate.

Learn more about custom shipping boxes.

What measuring tools do I need before packaging?

All you need are simple tools: a tape measure, calipers, or a ruler. These can accurately measure length, width, and height.

Don’t rely solely on the supplier’s specifications. Physical samples may vary by ±2–3 mm. Measuring them yourself will ensure the trays, dividers, and box fit properly.

- Always measure the longest side of your product (e.g., handle, cap).

- To test irregular products, we recommend using the “circumscribed rectangle” method: imagine the smallest cuboid it can fit into.

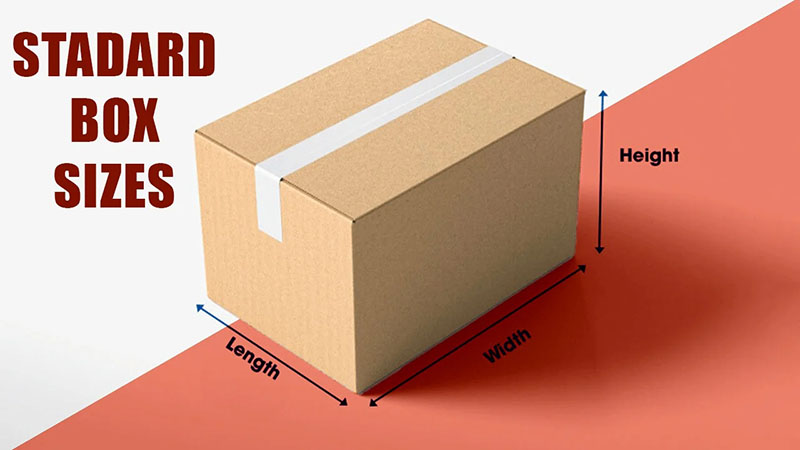

How to correctly measure the length, width and height of a box?

- Length: The longest side of the base.

- Width: The shorter side of the bottom.

- Height: The distance from bottom to top.

Leave at least 10–30 mm of space on each side for bubble wrap, foam, or honeycomb paper.

Should box dimensions be measured based on the inner or outer diameter?

Please use the inner diameter as a guide to ensure the product fits. Manufacturers often provide outer diameter dimensions, which include the thickness of the cardboard. For example, 5 mm thick cardboard will reduce the internal space by 10 mm. Be sure to confirm with the manufacturer before mass production.

How much space should be left for filler material?

- General: Leave 10–30 mm on each side

- Fragile items: Leave 20–40 mm on each side

- Lightweight and bulky: Minimize filling to reduce volume and weight

Too much filling = wasted space and money; too little filling = high breakage rate.

Common standard shipping box sizes for e-commerce

Common express fixed specifications (inches):

| Carrier | Small | Medium | Large |

| USPS | 8 ⅝ × 5 ⅜ × 1 ⅝ | 11 × 8 ½ × 5 ½ | 12 × 12 × 5 ½ |

| FedEx | 10 × 5 × 5 | 13 × 11 × 2 | 17 × 13 × 3 |

| UPS | 6 × 6 × 6 | 12 × 9 × 6 | 18 × 12 × 6 |

These boxes are convenient, but they may not be the most economical. For both branding and protection, custom shipping boxes are often a better choice.

How does product type affect shipping box size?

- Cosmetics & glass products: Small and compact, require EVA inner support.

- Clothing: Flat packed with minimal padding.

- Electronic products: Additional corner buffers must be reserved.

Different products have different rules. Ignoring these details will increase the risk of breakage and return rate.

How does box size affect shipping costs and dimensional weight?

The courier will calculate the volumetric weight (DIM):

Billable weight = the larger of actual weight and volumetric weight. If the box is too large, the volumetric weight will be much higher than the actual weight, and you will pay more.

Shipping box trends in 2025

In 2025, more and more e-commerce brands will prioritize optimizing shipping box sizes. To reduce costs and waste, they will reassess shipping box dimensions. Express delivery companies are also promoting eco-friendly packaging—smaller boxes = lower carbon footprint. The industry is establishing stricter packaging efficiency standards.

- On-demand carton cutting equipment: No need to stock up in the warehouse, orders can be cut at any time.

- Environmentally friendly corrugated cardboard: thinner and stronger, reducing costs.

- 3D scanning technology: Ensures that products fit precisely in boxes.

FAQs

Q1: How to calculate the volumetric weight of a shipping box?

Use the formula (length × width × height ÷ 5000 cm) and compare it with the actual weight, and take the larger one for charging.

Q2: What is the best box size for fragile items?

Leave at least 20–40 mm of space on each side and choose double-walled corrugated board.

Q3: Can I save money by customizing shipping boxes?

Yes. It reduces gaps, reduces volume and weight costs, and improves your customer experience.

Conclusion

Choosing the right shipping box size starts with measuring your product. Then, allow for cushioning, select cardboard strength by weight, and consider pallet and courier requirements. Avoiding boxes that are too large or too small can save costs while protecting your product and brand.

- Measure physical product samples.

- Allow 10–40 mm of buffer space.

- Compare the volumetric weight with the actual weight before shipment.

- Consider using custom packaging to improve efficiency and experience.

👉 Contact Xiangge Packaging to get free die-line and shipping box customization solution.

About Xiangge Packaging

Xiangge Packaging has over 10 years of export experience, specializing in corrugated boxes, gift boxes, and e-commerce packaging. We help global brands design the right packaging, saving shipping costs and improving the customer experience. We offer low minimum order quantities and free design support.

Last updated: September 2025